Keeping an eye on future market developments, MOCOM is developing innovative concept cases that demonstrate material solutions for complete assemblies – and is thus positioning itself even more strongly as a future-oriented solution provider for its customers: The virtual case studies present novel plastics applications with great growth potential, for example in driver assistance systems.

MOCOM offers plastic solutions for complete assemblies and “Design for Recycling”

The aim of the MOCOM concept cases is to present approaches to solutions that demonstrate the advantages of plastics in existing applications or those currently under development. ” Prerequisites for creating these concept cases are technical and market knowledge as well as anticipatory thinking. In these virtual case studies, we present various plastics solutions for each individual component in relation to the entire assembly,” explains Kurt Maschke, Senior Director Global Marketing Automotive at MOCOM. “We already want to offer solutions for challenges that our customers will increasingly face in the future.” These include, for example, sustainable composite materials based on recycled raw materials, lightweight plastics that provide greater efficiency and sustainability, or fire protection solutions (also with composite materials based on recycled raw materials) that meet various UL94 classifications. All products are individually adapted to specific customer requirements if necessary. Customers also benefit from the accompanying qualified advice provided by the MOCOM technical and market experts.

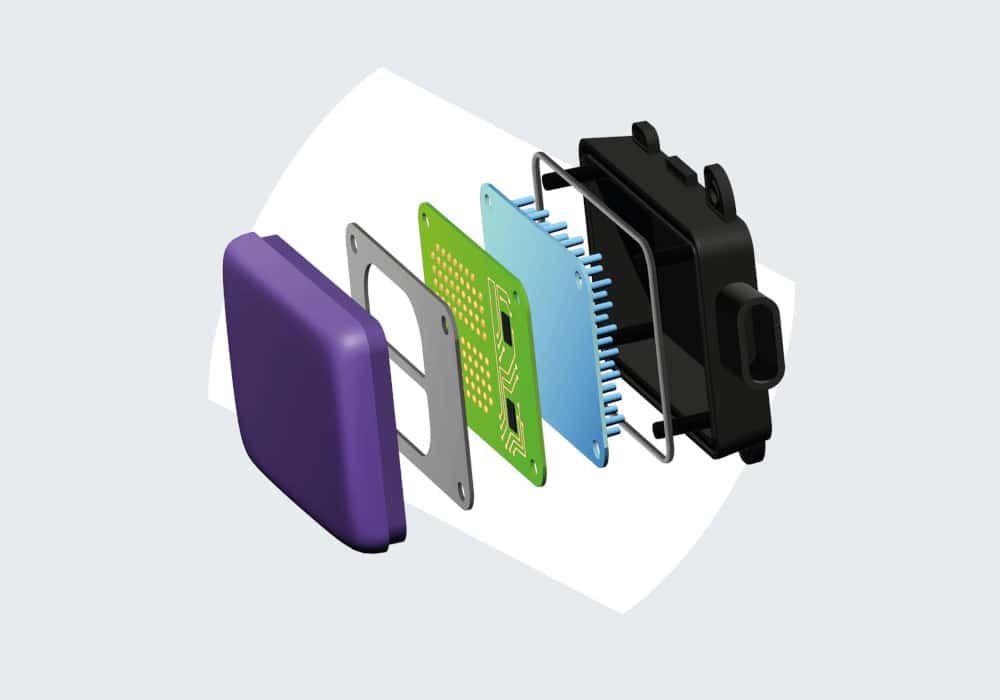

An initial concept case has been developed by MOCOM for radar sensors, which are used in particular in cars, for example, for distance measurement. Here, it is important to consider how the radar operates at different frequencies and, in detail, the effect of the radome materials used on its performance. MOCOM offers specially suitable plastics for the individual components of the radar – and has from the outset the use of possible recyclates or recyclability (designing for recycling) in mind: For example, the radar-transparent front panel (radome) can be produced from radar-permeable materials such as Alcom® LD, LDDC, LG, Altech® or Altech NXT PP® – of course, recyclates can also be used here. For the radar-absorbing intermediate plate, MOCOM offers various materials, such as Alcom® HP, Altech® or Altech® ECO. The thermally conductive heat sink can be made from Alcom® TCE or Alcom® TCD, seals from Alfater XL® or Alfater XL® ECO. Alcom® EMI and Tedur® are suitable for the housing, which is also used for electromagnetic shielding.