LEONHARD KURZ presents innovative machines, efficient processes, and recycling materials

As a pioneer in the plastics processing industry, LEONHARD KURZ already offers series-ready solutions to lower energy consumption, reduce waste, and make the entire life cycle of products sustainable. FAKUMA 2023 offers the Fürth-based thin-film specialist the opportunity to present innovations that drive the sustainability goals of the industry – from recycling materials, through resource-efficient machines and production processes, to recyclable end products.

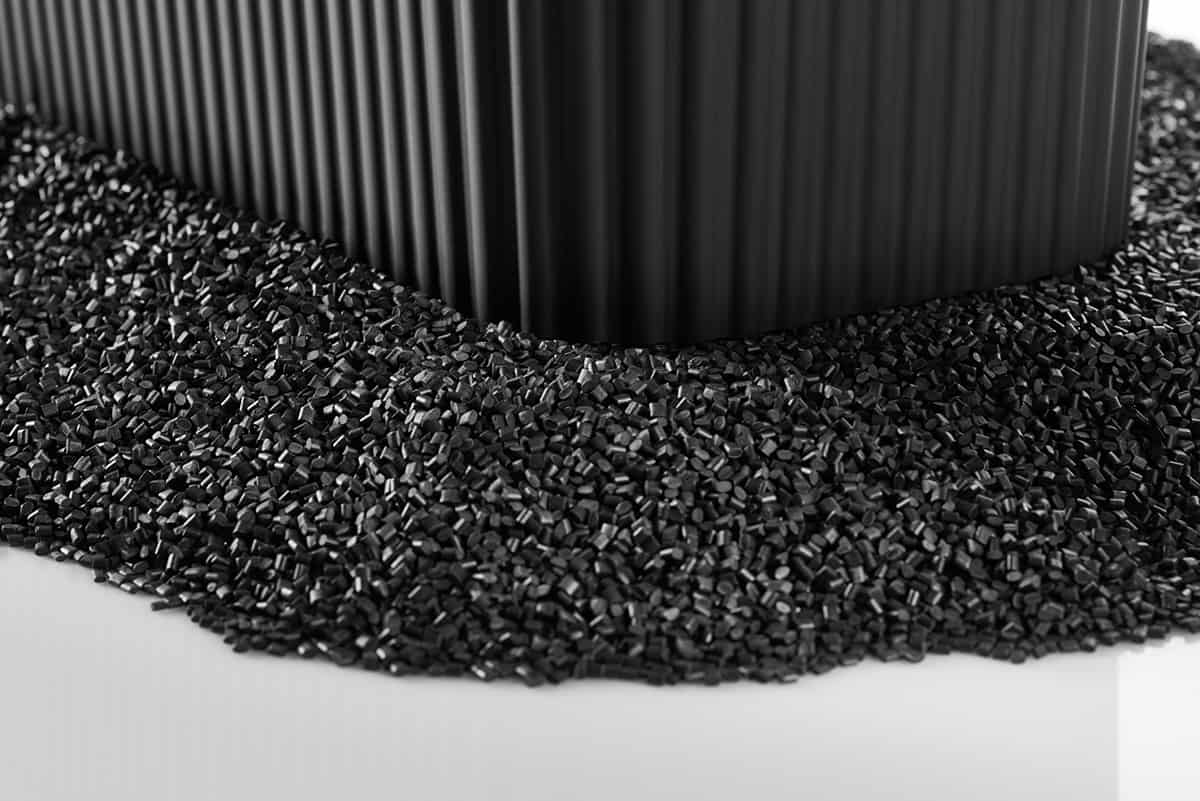

RECOPOUND®: Waste becomes a new material

FAKUMA visitors have the opportunity to experience the latest developments in the field of sustainable plastics processing up close at the KURZ stand and at the stands of our partners ARBURG and DECKERFORM. There are also several products made from the post-industrial recycled material RECOPOUND®. Rainer Süßmann, Executive Senior Vice President of Business Area Plastic Decoration, explains: “KURZ is continuously increasing the proportion of recycled and bio-based materials and has set itself the goal of maintaining the recyclability of end products and components and constantly optimizing its own decoration processes and solutions.” Various exhibits will be on display at FAKUMA 2023 – including clothes pegs made from RECOPOUND® and finished with hot stamping (DECKERFORM), add-on parts for a tool case (ARBURG), a window box developed together with the Munich-based start-up Greenling, and other sample parts made from RECOPOUND®.

Efficient machines, sustainable processes

A joint project will be presented at the DECKERFORM stand. Here, a door strip for the automotive sector will be shown, which is produced using resource-saving spray foaming and consists of a high-quality PC/ABS (PIR) compound from the Nuremberg-based company Sysplast. It is refined with an indium metallization in the energy-efficient IMD process (IMD indium transfer system). The big advantage of the spray foaming process used is that less material is required and the finished component is therefore light in weight but still very strong.

Please log in to read the full article

All our content is free and accessible after logging in. You can register for a free account below.