Evonik is extending its portfolio of elastomeric materials for powder bed fusion 3D printing technologies. The specialty chemicals company is launching with INFINAM® TPA 4006 P a new powder grade that is especially optimized for all types of open source SLS 3D printing machines. Evonik will present its new flexible material during the Formnext trade show, Frankfurt am Main Germany, November 7-10, 2023 in hall 12.1 at booth C39.

Evonik launches new INFINAM® TPA elastomer powder material for SLS 3D printing

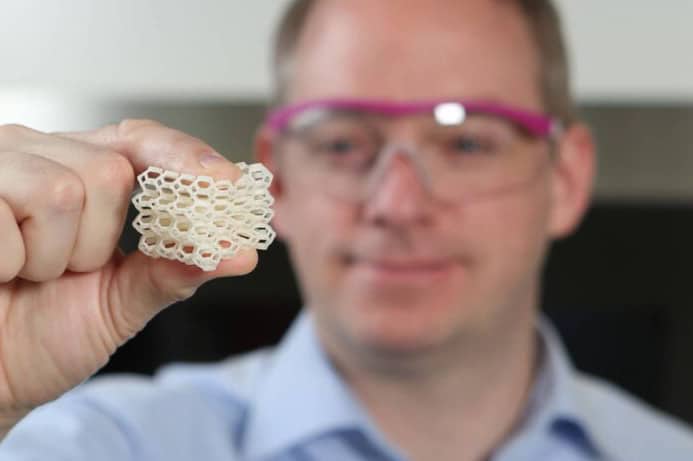

INFINAM® TPA 4006 P is a PA12 elastomer consisting of polyamide 12 segments and softening segments and is characterized by rubber-like properties and outstanding impact strength and thus excellent rebound behavior.

Evonik’s new 3D printing elastomer features high process stability and excellent powder flow properties making it perfectly suitable for all types of SLS technologies available on the market today. Furthermore, the new fine powder can be manufactured with reusability rates of 50/50 virgin vs. used material.

EXCELLENT REBOUND BEHAVIOR MEETS FOOTWEAR APPLICATIONS

“Elastomer-based 3D printing applications play a crucial role of the additive value proposition. Mostly like limited editions of infinite designs or high customization they perfectly showcase what 3D printing stands for”, says Arnim Kraatz, Director Powder Bed Fusion at Evonik. “By offering new optimized 3D printing materials, we enable our customers to take advantage of the unique set material properties in order to explore and scale up new applications.”

3D printed parts from INFINAM® TPA 4006 P show an excellent surface resolution and feature detail while exhibiting outstanding durability over a wide temperature range from -40°C to 90°C. The powder is also ideally suited for manufacturing of functional 3D high-tech plastic parts – for prototypes as well as series products. Furthermore, TPA has been used for decades as material of choice for a variety of consumer goods applications like footwear.

Evonik’s range of elastomeric 3D printing materials includes two types of powders for powder bed fusion 3D printing technologies:

- thermoplastic amide INFINAM® TPA

- thermoplastic copolyester INFINAM® TPC

INFINAM® FL, a rubber-like photopolymer resin for photo-curing 3D printing completes the current portfolio of elastomeric materials for industrial 3D printing.

DRIVING 3D PRINTING AT SCALE

Evonik’s 3D printing activities are bundled in the group’s Additive Manufacturing Innovation Growth Field. The strategic focus is on the development and manufacturing of industrial, ready-to-use high-performance materials for all major polymer-based 3D printing technologies. As such, the specialty chemicals company continues to advance 3D printing as a large-scale industrial manufacturing technology across the entire value chain.